Lean Philosophy

Lean Philosophy

Go Lean to Get Under Budget & Ahead of Schedule

Many people in the healthcare and higher education fields have become familiar with lean practices and implementation in recent years, but when discussing construction a lot of people confuse Lean Construction with LEED (Leadership in Energy and Environmental Design). There are many tools and practices of Lean Construction which improve project results, increase value to the owner, reduce waste, and improve efficiency throughout the project.

One of the many Lean processes Beckenhauer Construction is implementing on all of our projects is Pull Planning. Pull Planning truly incorporates and utilizes everyone on the project teams expertise, each foreman in a pull planning session is engaged and communicating with the others in regard to what they will deliver and what they need to perform their work. Each contractor identifies what they need completed before they can do their work, working from the back of the schedule towards the front in the scheduling process VS the traditional push of the schedule from beginning to end that most general contractors employ.

We have read in many articles that the traditional way of scheduling construction activities leads to just over 50% of those activities actually being completed each week. With about a 50% PPC (Planned Percentage Complete) it is no wonder so many project schedules have issues! We have found using pull planning, our PPC can range between 70% to 100% and this results in very reliable and early turnover of projects.

While the pull planning and measurement of PPC greatly improves the weekly subcontractor meetings, a detailed CPM schedule (Critical Path Method) is still maintained, and 6 week look ahead schedules are still sent out and communicated to all involved. All of these schedules are reciprocal, feeding back and forth the information on planned and completed work activities.

On our Cherry County Hospital Project we recently started the project off with a full day, pull planning session. By the end of the day the team had completed the pull planning process for the two additions through building enclosure and found that with everyone’s input the schedule had the potential to be reduced by 25%!

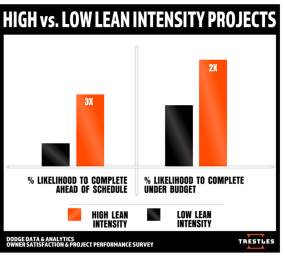

So why is this important to everyone involved? Recent information in a report from Dodge Data & Analytics where they had surveyed 81 owners and 162 projects found that projects that implemented more Lean methods (such as management methods, team organization and contracting terms) were two times more likely to complete under budget and 3 times more likely to complete ahead of schedule!

When you are planning your next project consider implementing Lean construction and you are likely to see improved results! And of course, consider calling Beckenhauer Construction Inc. to see how we can help facilitate that.