Safety Talk with BJ

Safety Talk with BJ

Safety Director BJ Wilkinson

If you are like me, you do things on ladders at home that you know better than to do at work. Wrong size ladders, standing on rungs or the top, over-reaching with tools and throwing off your balance, you name it, I’ve done it. I’ve assumed more risk than I should have. I’ve even argued with my spouse, who pointed out it looked dangerous, saying I was a trained professional and would only be up there a minute. Sound familiar?

A full 20% of all worksite injuries occur with ladder misuse as a root cause. Many happen on ladders 5 feet or less off the ground, often stepladders, just like the ones you use at home. In 2024, OSHA reported over 22,000 ladder injuries, highlighting the need for continued safety measures and training. The most common causes include incorrect setup, using the wrong ladder, and failing to inspect equipment.

While injuries remain high, safety training and awareness are increasing. Nearly all organizations now offer ladder safety training, which is a step in the right direction. Still, accidents often stem from incorrect setup, using the wrong ladder for the task, or ignoring damaged equipment. Human error also plays a role, like not maintaining three points of contact or carrying tools while climbing.

To address these risks, organizations are making ladder safety training standard, often with annual refreshers. OSHA provides guidelines, and National Ladder Safety Month promotes awareness. Selecting the right ladder, ensuring it’s in good condition, and following manufacturer instructions are essential to prevention.

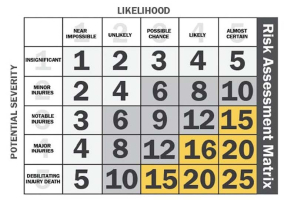

And then, there’s risk analysis. At home, it’s easy to ignore because no one is watching. Here’s a better option:

1. Elimination of Risks – Perform tasks from the ground or with extendable tools to avoid working at heights.

2. Collective Systems – Install guardrails or safety nets for passive protection.

3. Work Restraint Systems – Harnesses or tethers that prevent reaching hazard zones.

4. Fall Arrest Systems – Last-resort equipment designed to stop a fall in progress.

By following this hierarchy, organizations can address risks systematically, comply with safety regulations, and build a stronger safety culture. I even printed the chart and taped it to my ladder rack in the garage as a reminder.